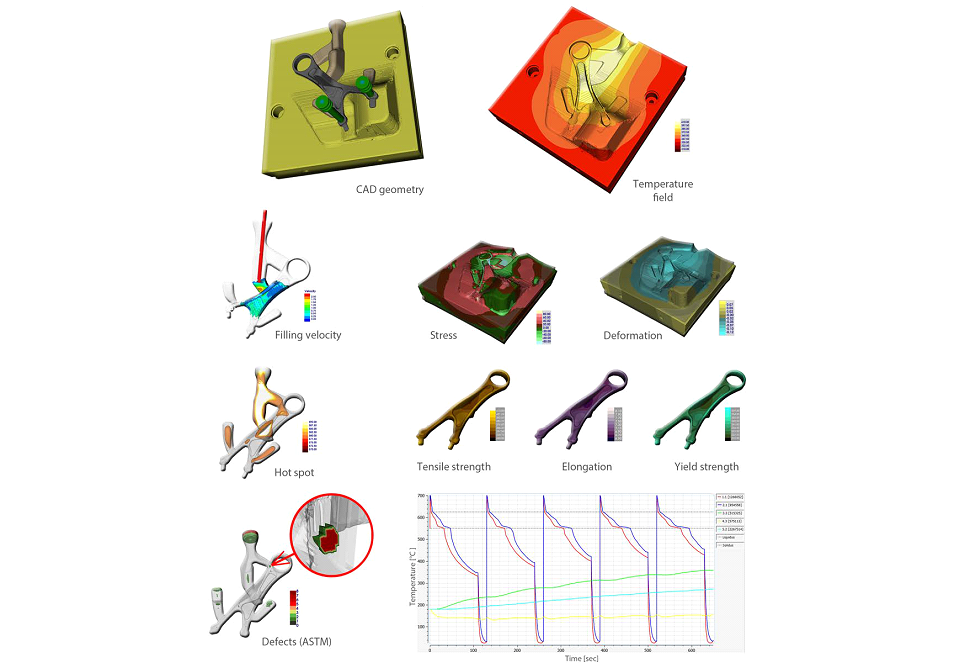

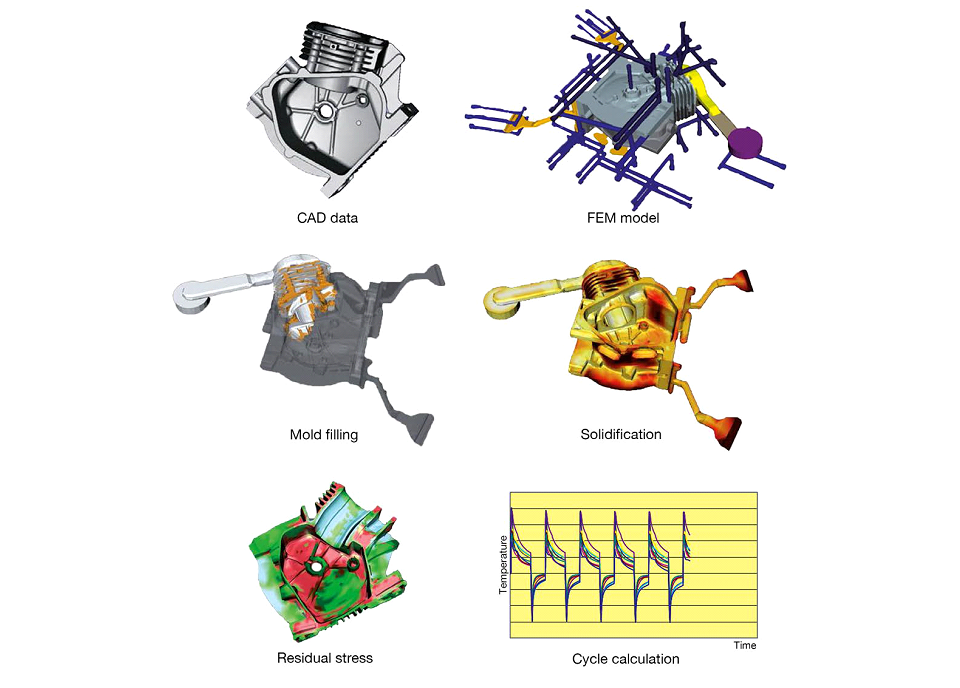

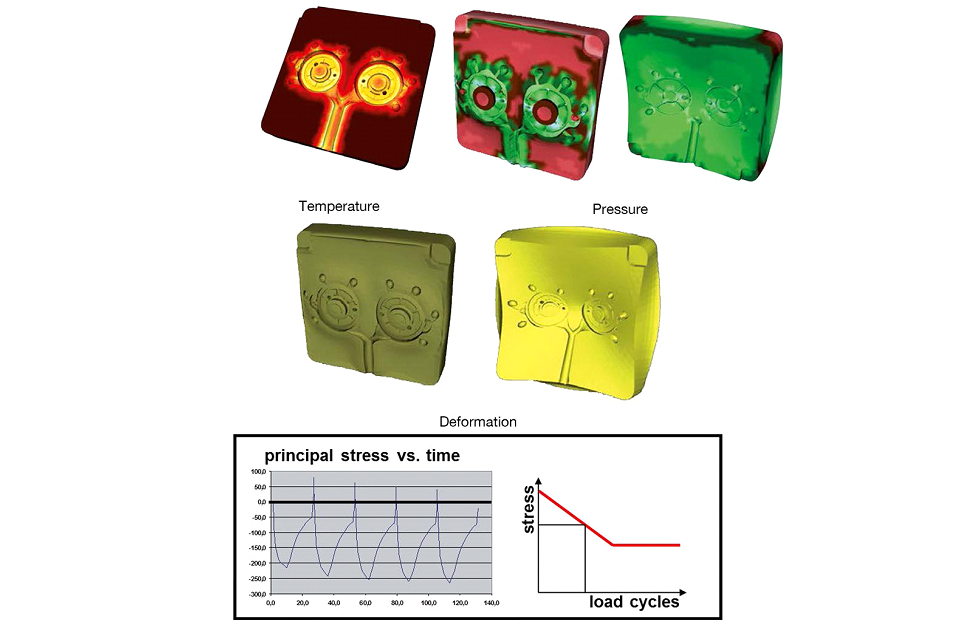

The simulation of solidification is the base for the prediction of porosities, residual stress and deformation. Several cycles are calculated to draw near the steady state.

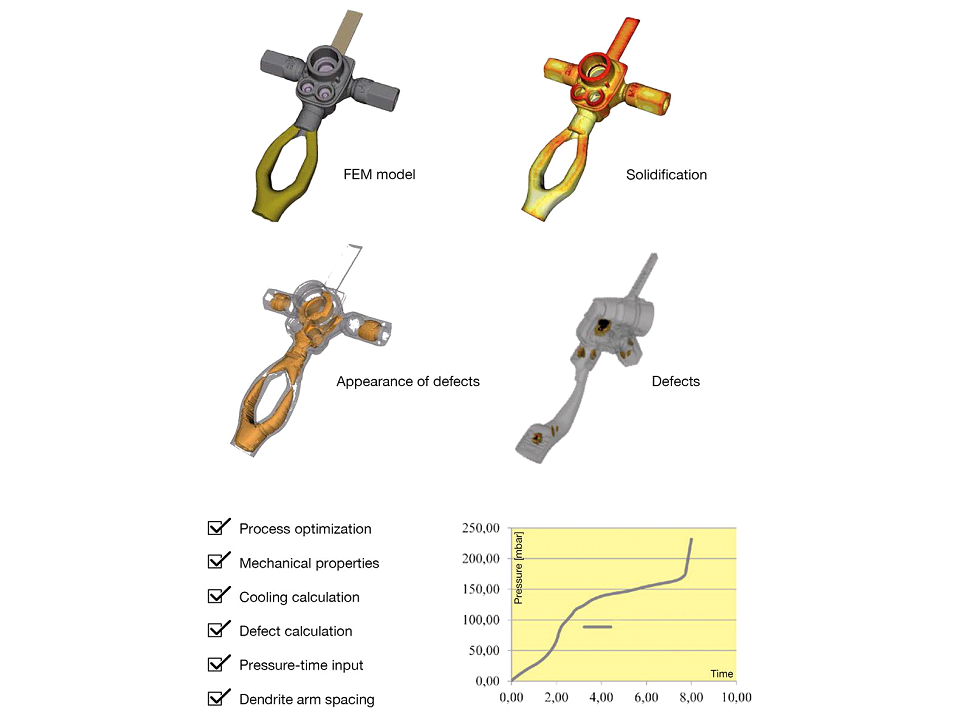

Precise geometry with high level of detail is the reason for real success.

Optimized riser and gating system leads to a minimal deformed part. Simulation of temperature, solidification, stress and deformation are the keys to reach optimum.

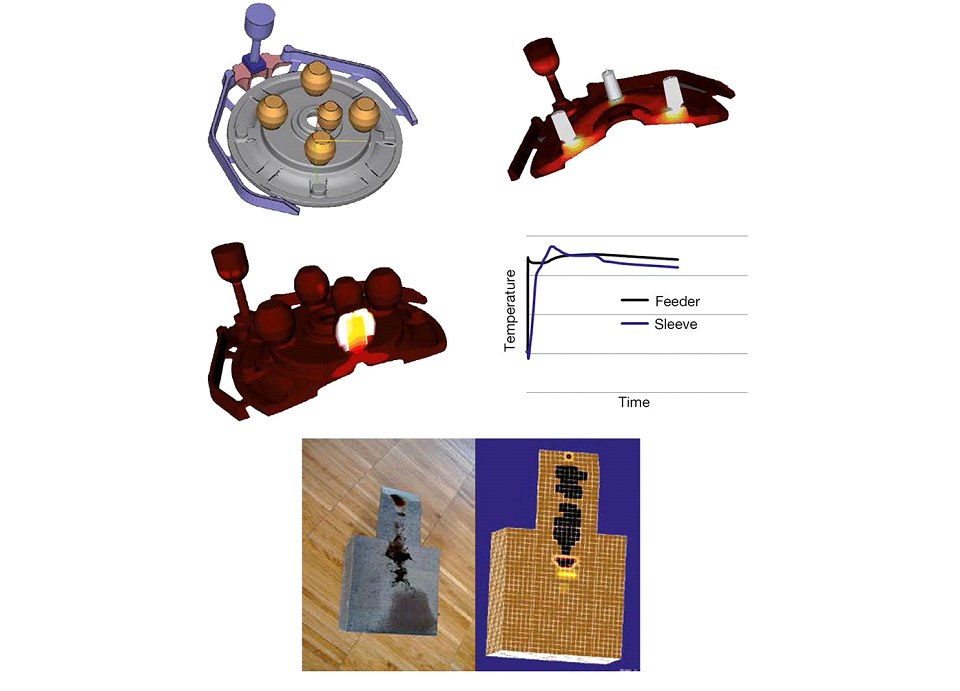

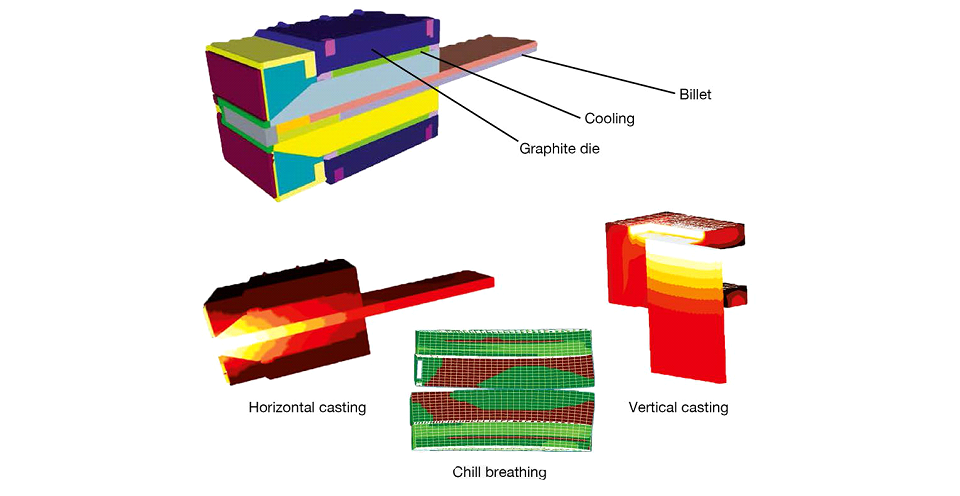

The thermal and mechanical equations are coupled. Thus the material flow and the shrinkage of the billet can be determined as well as the gap formation and gap dependent heat transfer.

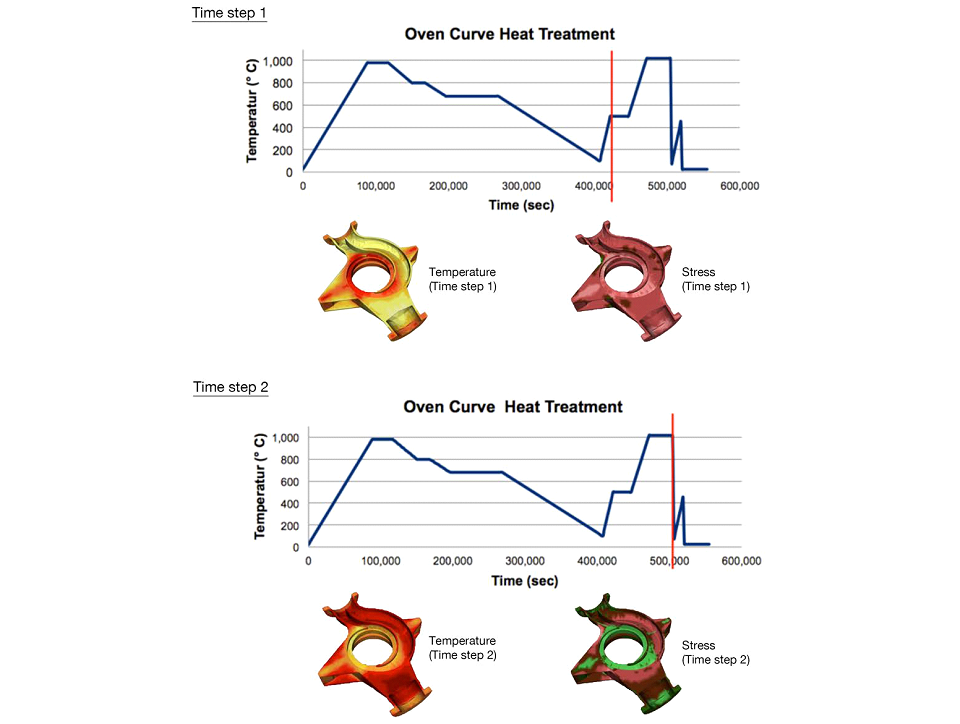

The changing residual stresses while heat treatment can be calculated in order to optimize the oven curve to reduce deformation.

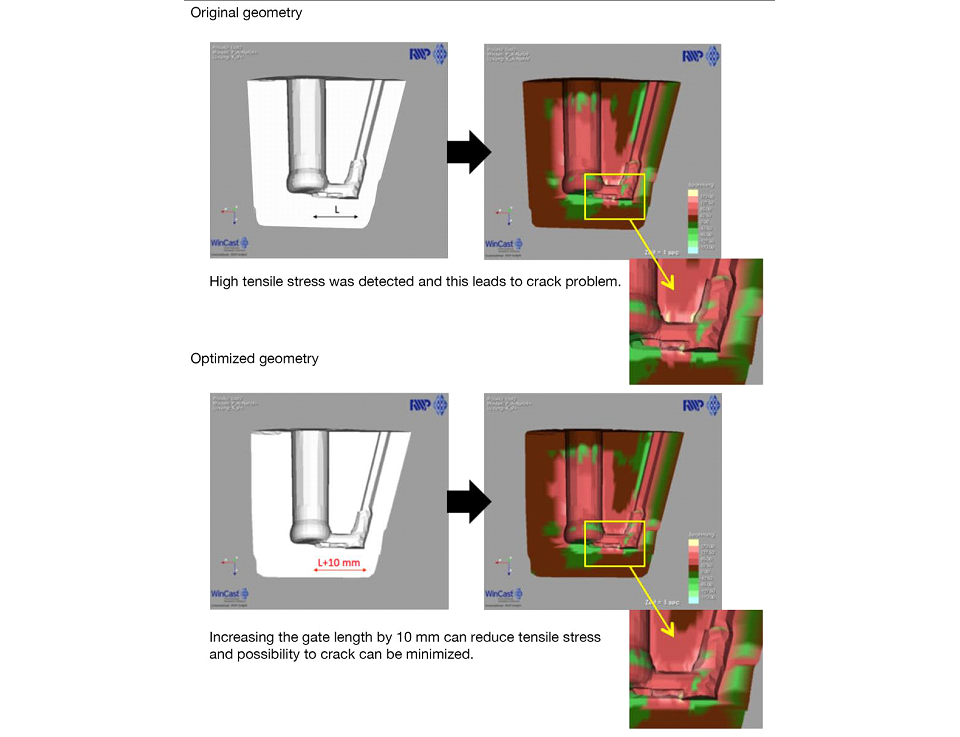

High differences in temperature during a high pressure die casting cycle and enormous pressure peaks are the reasons for local cracking in the die and reduce the lifetime significantly.

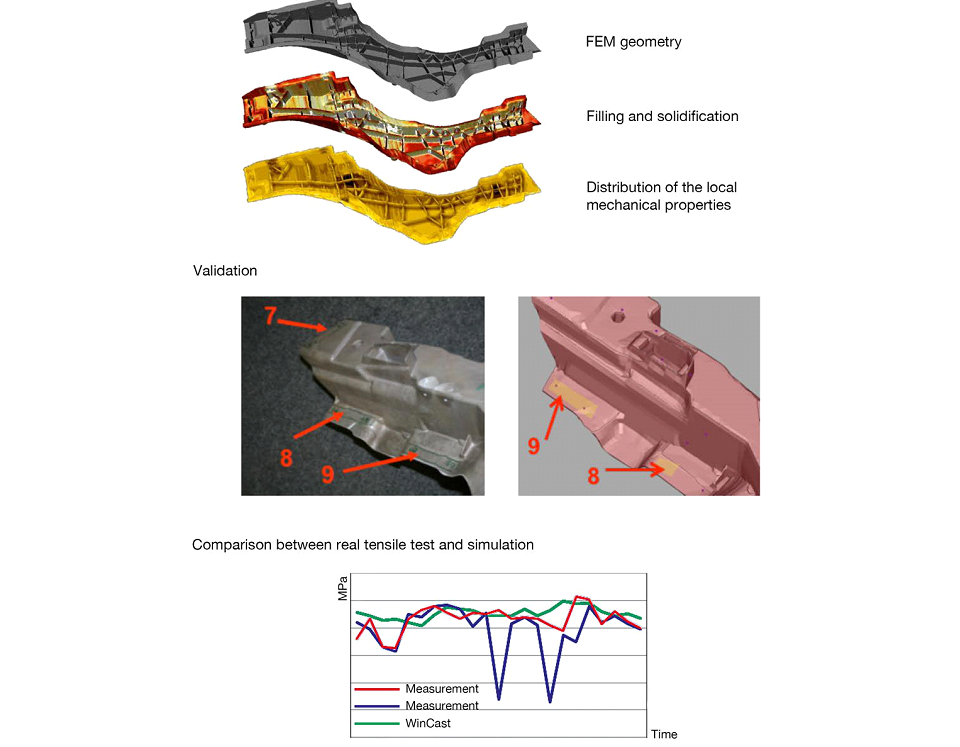

Complex thin-walled aluminum casting.