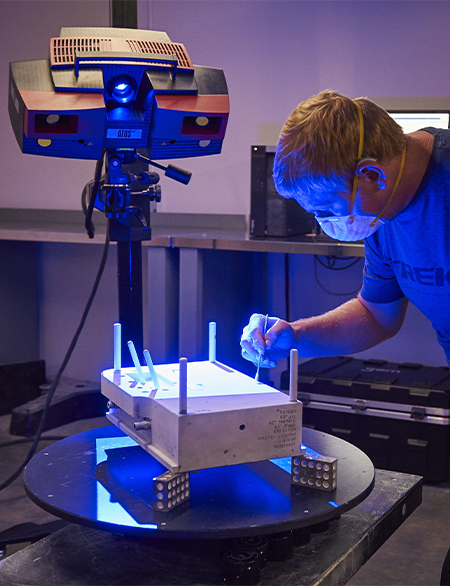

For part inspection, analysis, reverse-engineering, design, historic/art preservation and more, 3D scanning is a quick, thorough and cost-effective method for capturing real-world objects in digital space.

The process of collecting data points of a surface to accurately represent an object in digital three-dimensional space. The data points are recorded on an XYZ coordinate system. As points are collected, they cover an object’s surface creating a “point cloud” in the exact shape and size of the object. The point cloud can then be rendered into a mesh (.STL) where all the points are connected with lines to create a surface made up completely of triangles.

3D scan data allows an object to be examined and measured digitally. There are two main avenues to utilize scan data: Inspection (dimensional analysis) and Reverse-Engineering (object replication).

Almost any object can be 3D scanned regardless of size, shape, material or even location.

Checkout some of the other client's we have worked with here.